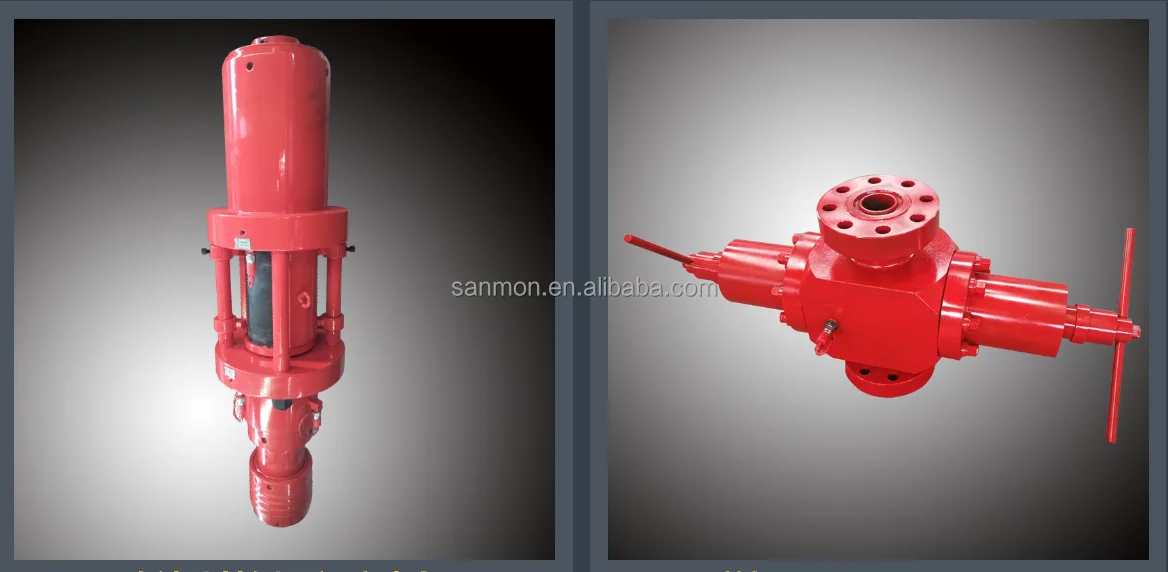

Product name: Blowout prevention box-side door blowout preventer

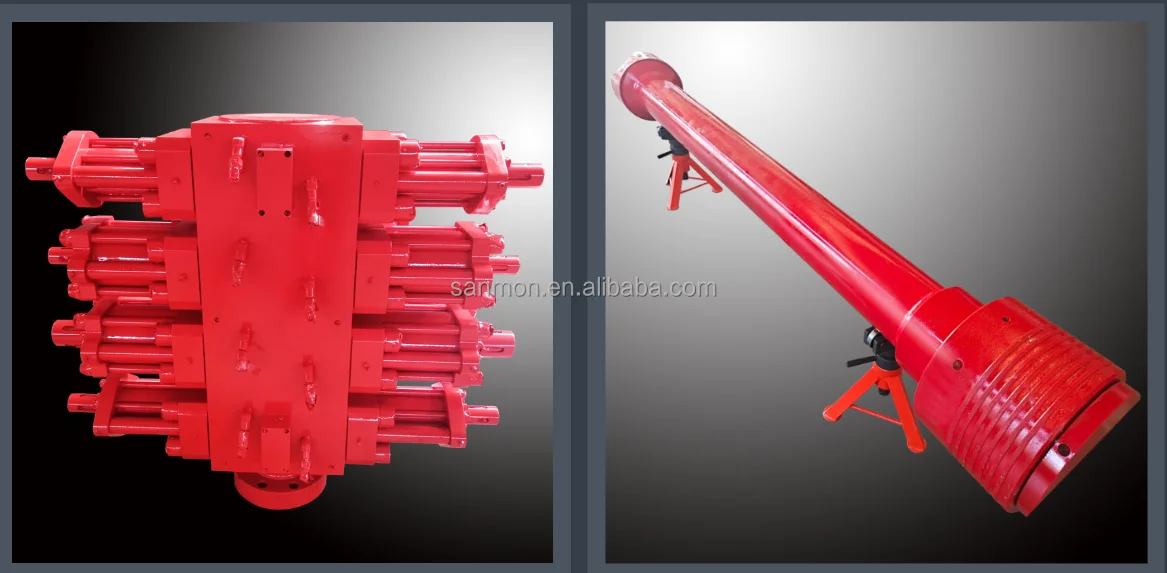

Stripper packer assembly consists of top hydraulic cylinder, bushing assy, top piston, cylindrical shell, tubing, bottom

piton, bottom hydraulic cylinder, side door and other parts. The bottom buttress-thread of side door stripper assembly can connect with the top buttress-thread of quad ram BOP, and between them the lubricator and blowout sub can be connected with the piezometric at the bottom of port Side door BOP can connect with hydraulic pipeline to lead the port on the ground, and can be convenient to read the actual numerical value of wellhead pressure. During the operation, from the stripper assembly down cylinder "rubber cylinder compression" oil mouth through the outer hydraulic system pressure (maximum control pressure 21Mpa) can make into stripper assembly rubber cylinder compression deformation closed the coiled tubing and the gaps between the rubber tube and sealing fluid.It is easy to replace the Packer Element. In the process of operation, the replacement could be done when closing half-sealing ram and opening side door & up piston. It is no need to pull out tubing, which saves much time.

Side Door Stripper Packer

* Simple configuration and compact size.

* Single hydraulic passage provides a clear layout, easy for connection.

* Single hydraulic passage requires less seals, reliable and easy to maintain.

* Side door design allows fast replacement of packer and bushing.

usage:

Dynamic sealing of coiled tubing for up and down well operations.

Technical parameters:

Working pressure: 35MPa, 70MPa, 105MPa

Seal oil pipe diameter: 1", 1.25", 1.5", 1.75", 2", 2.375", 2.875", 3.5"

Applicable environment: crude oil, natural gas and water containing H2S

Temperature grade: T-20 (-29℃~+121℃)

Material grade: 75K (60K, 45K, 36K)

Connection method: ACME union thread

Features:

1. The rubber cartridge can be replaced during coiled tubing operation;

2. The main pressure-bearing parts are made of high-quality alloy steel forgings, which have good comprehensive mechanical properties;

3. Resist H2S, resist corrosion and extend service life.